M-POWER

Manufacturing Technologies

M-POWER delivers a full range of advanced manufacturing technologies designed to drive performance and innovation across industries. From precision machining, casting, and forging to stamping, molding, and fabrication, we combine world-class capabilities with deep technical expertise.

Our vertically integrated approach ensures that every part, component, and assembly meets the highest standards of quality, consistency, and efficiency — helping our customers bring better products to market, faster. Our specialized manufacturing technologies include:

Machining

CNC, VMC, HMC, and gang drilling, with advanced gear cutting, centerless grinding, hobbing, friction welding, and laser welding. Multi-axis machining up to 5-axis capability ensures precision and flexibility for complex parts.

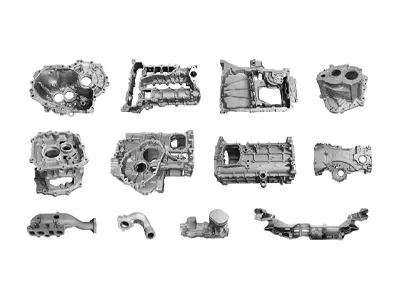

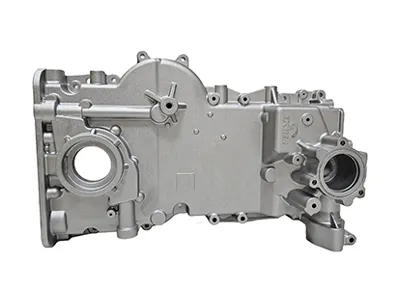

Casting

High-pressure molding lines for ferrous and alloy castings (0.50kg–200kg) with annual capacity of 200K MT. Non-ferrous alloy castings (0.25kg–150kg) produced using HPDC, LPDC, and gravity processes, supported by machines up to 4,000MT.

Forging

Hot, warm, and cold forging of ferrous and non-ferrous alloys, from 0.25kg to 150kg. With annual capacity of 200K MT, our forging solutions deliver strength, durability, and performance across diverse applications.

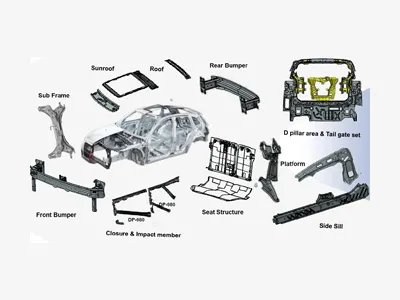

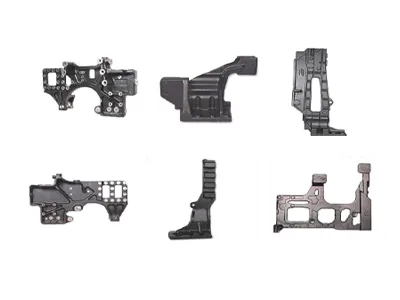

Stamping, Fine Blanking & Roll Forming

Progressive and tandem stamping, fine blanking, and roll forming for ferrous and non-ferrous materials. Press sizes range from 50MT to 3,500MT, with annual capacity of 200K MT for high-volume, consistent output.

Plastic Molding

Horizontal and vertical injection molding and blow molding for interiors, exteriors, engine, and chassis systems. Class-A surface capabilities and 100K MT annual capacity support precision parts with exceptional finish.

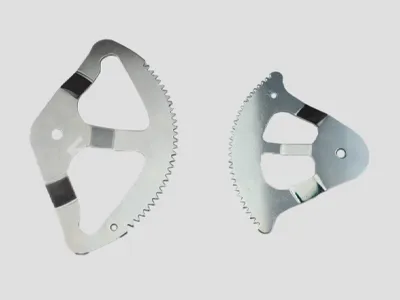

Gear Blanks & Cutting

Transmission, engine, and driveline gears and shafts manufactured with forging, heat treatment, precision machining, and gear testing. Annual capacity exceeds 20 million units, ensuring scale and reliability.

Extrusions

Horizontal presses up to 12-inch diameter for aluminum profiles in alloys up to 7-series. With 100K MT annual capacity, extrusion capabilities provide lightweight, high-strength solutions for multiple industries.

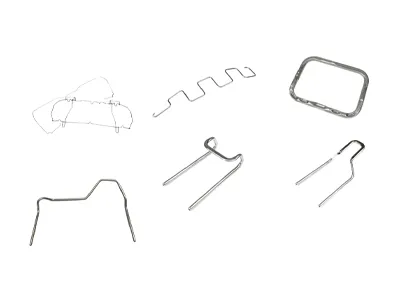

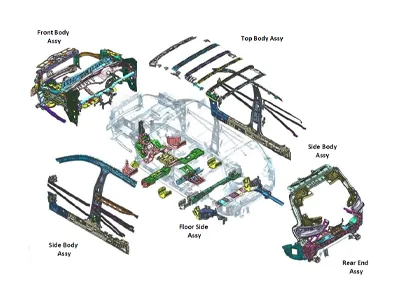

Fabrication

Advanced assembly and welding with robotic processes including laser, MIG, TIG, spot, seam, and projection welding. With over 2 million units annually, we deliver strong, consistent, and efficient fabricated structures.

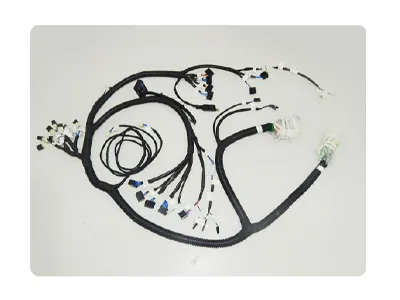

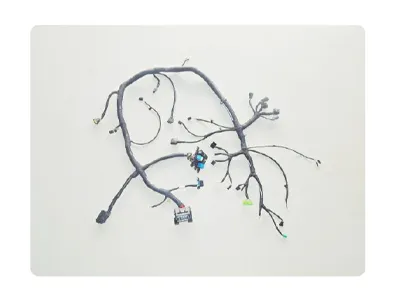

And MORE

Additional specialized capabilities include wire harness production, electronic components, and integrated systems designed to expand product functionality and performance.